In my free time, I designed a wooden standing desk specifically for my anthropometrics and my new room. It was designed to fit a mini fridge underneath, a printer and have lots of storage available with baskets. The machining process was done with the help of my Dad and his wood shop.

Process

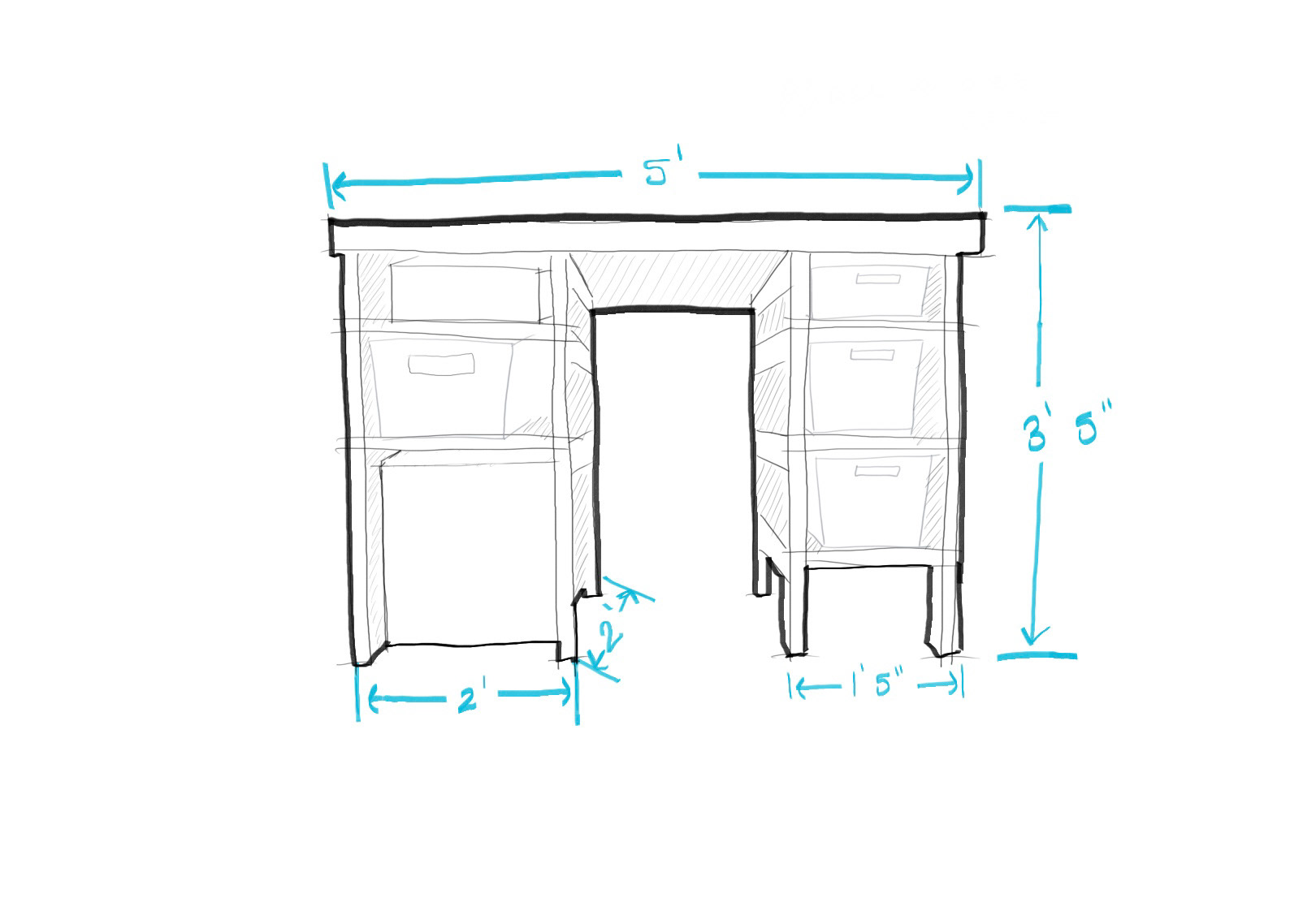

Measurements

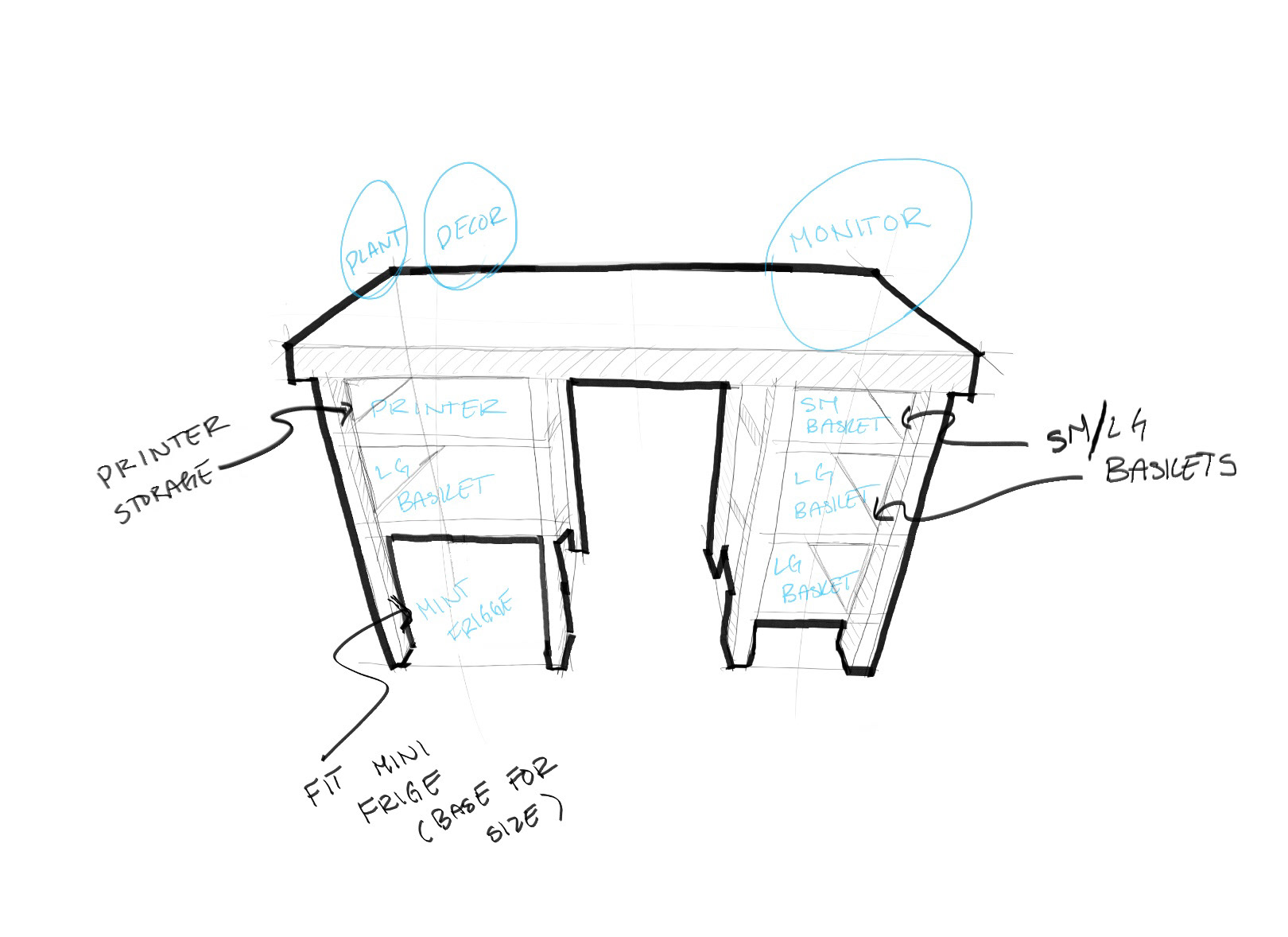

Rough Layout for Storage

The process consisted of measuring, sanding, nail gunning, painting, priming, more sanding, gluing lap joints and.... even more sanding.

MEASURING

DRILLING

NAIL GUNNING

UNDERSIDE OF THE TOP

SANDING THE TOP SIDE

The design involved having two thick legs with shelves to support the oversized top. Since there was three different pieces (eg. two legs and the top), this allowed for easy transportation and set up/take down. No bolts or screws were need for the final assembly which allowed for the desk to be adjusted to whatever environment it was in, such as it allowed the legs to be swapped if needed since the mini fridge needed to be near an outlet.

BASKETS STORAGE

LEG

BEFORE PAINTING

SIDE VIEW

Final Product In Context

Top View