We were required to design a unconventional, user-friendly, mass produced bird house for a specific type of bird, while still being aesthetically pleasing. My design was inspired by mailboxes and included a cleaning door, a detailed logo engraving, and a simple geometric shape.

Primary Research

The first stage of the process was learning about purple martins. A fellow design student and myself went to a local purple martin housing location to see the current design up close and the learn from a bird expert. I also went to the Museum of Nature in Ottawa to see their bird display to learn more since the end user was not just the birdhouse caretaker, but also the bird.

Purple Martin at Museum of Nature

Housing at Sailing Club

Housing at Sailing Club

Secondary Research

From my primary and secondary research, I learned the housing requirements purple martins need. In summary, the birds need a well ventilated house with a way for the human to clean it, it needs to be minimum 6"x6" and the houses need to be grouped together since they are a community bird. For insulation, the house needs to have a white exterior to reflect the sun and the walls need to be 3/4" thick for proper insulation.

About Purple Martins

Current Housing

House Requirements

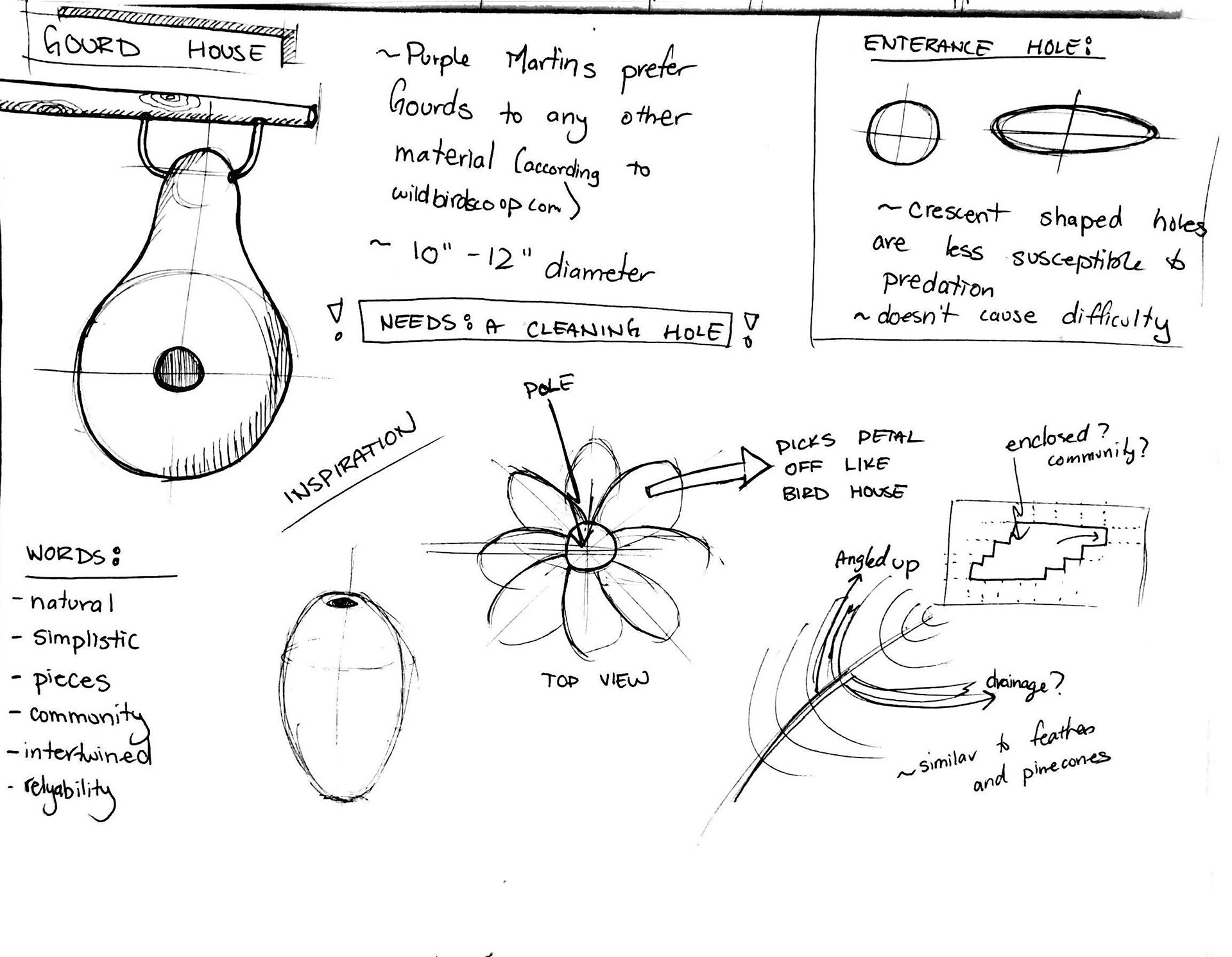

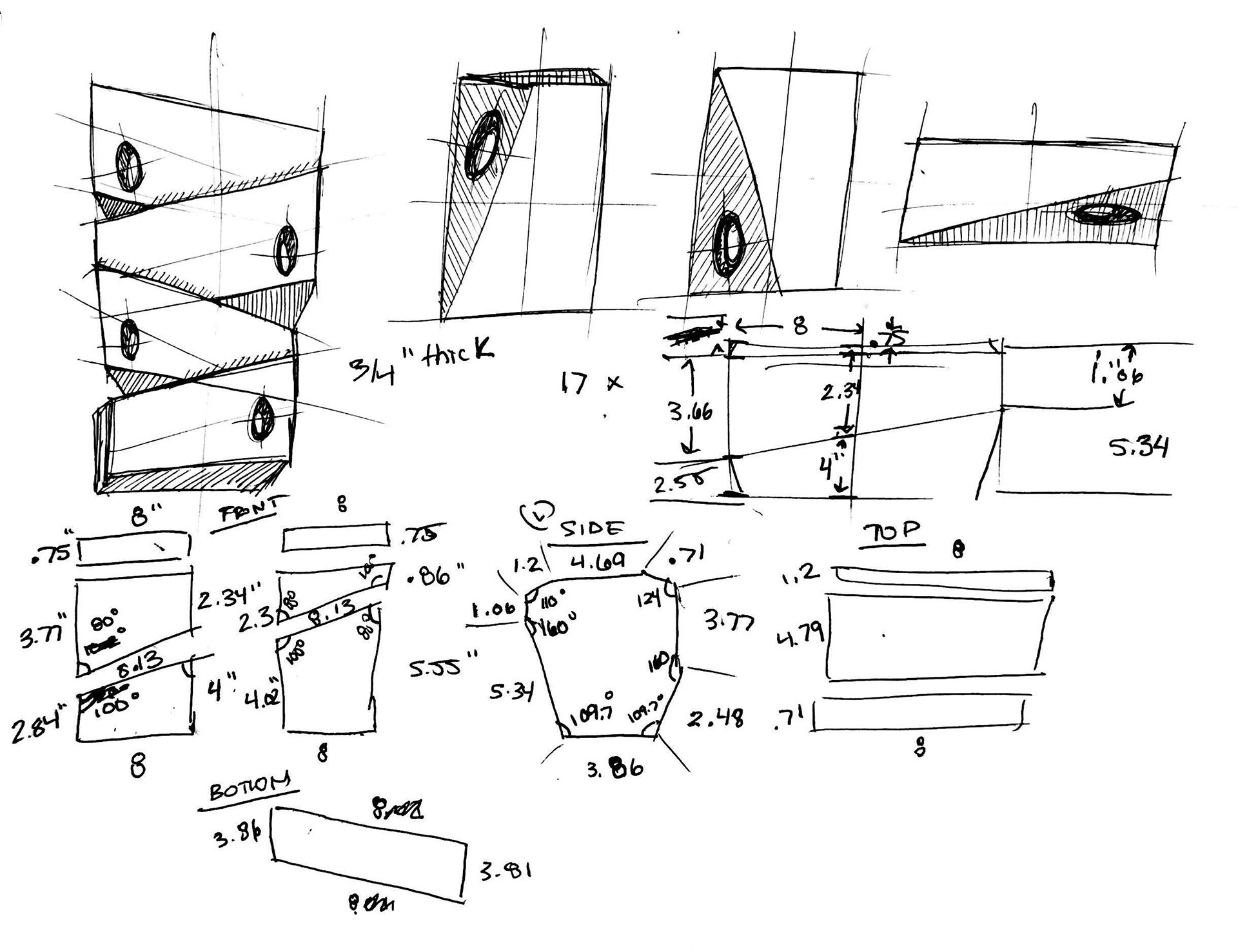

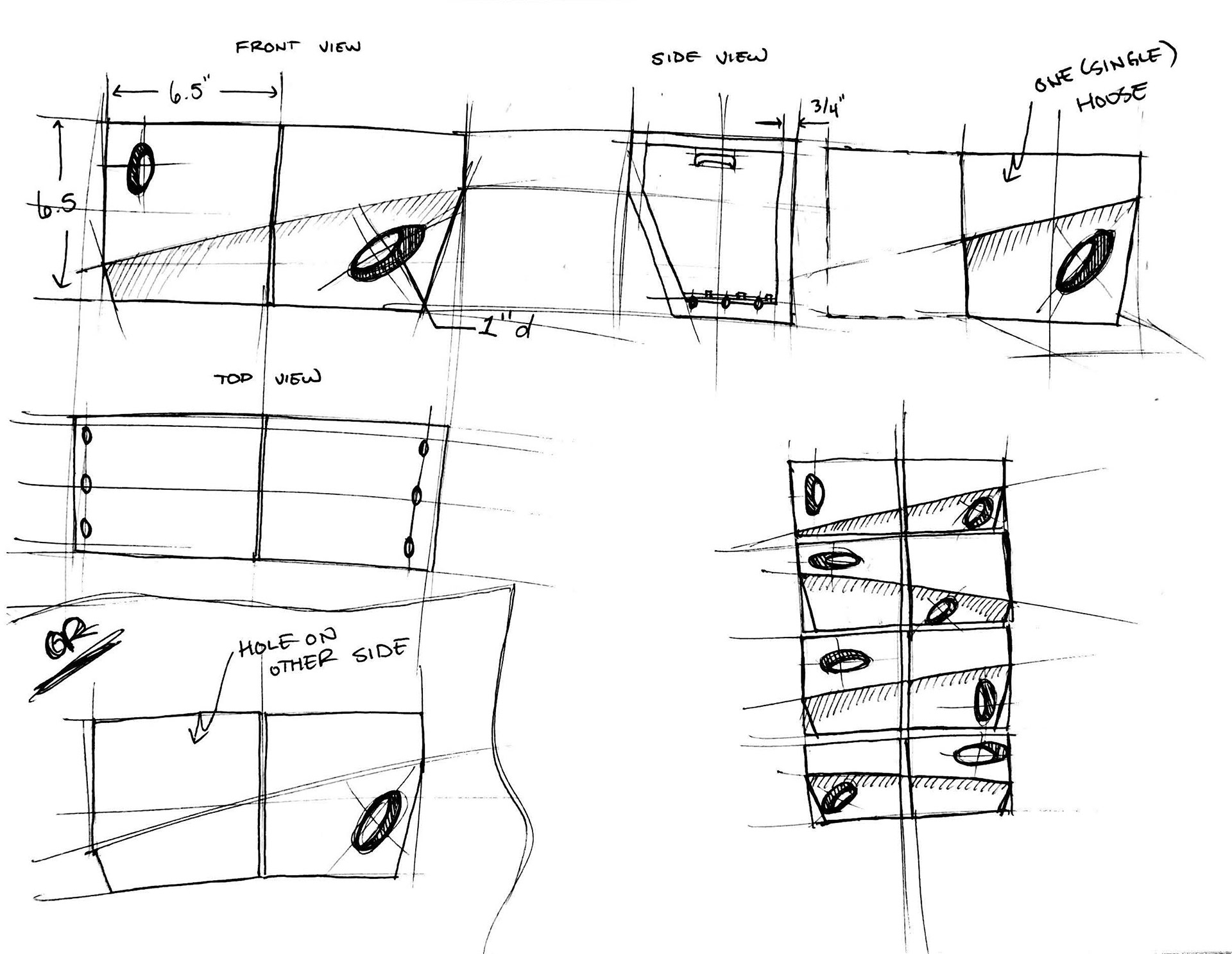

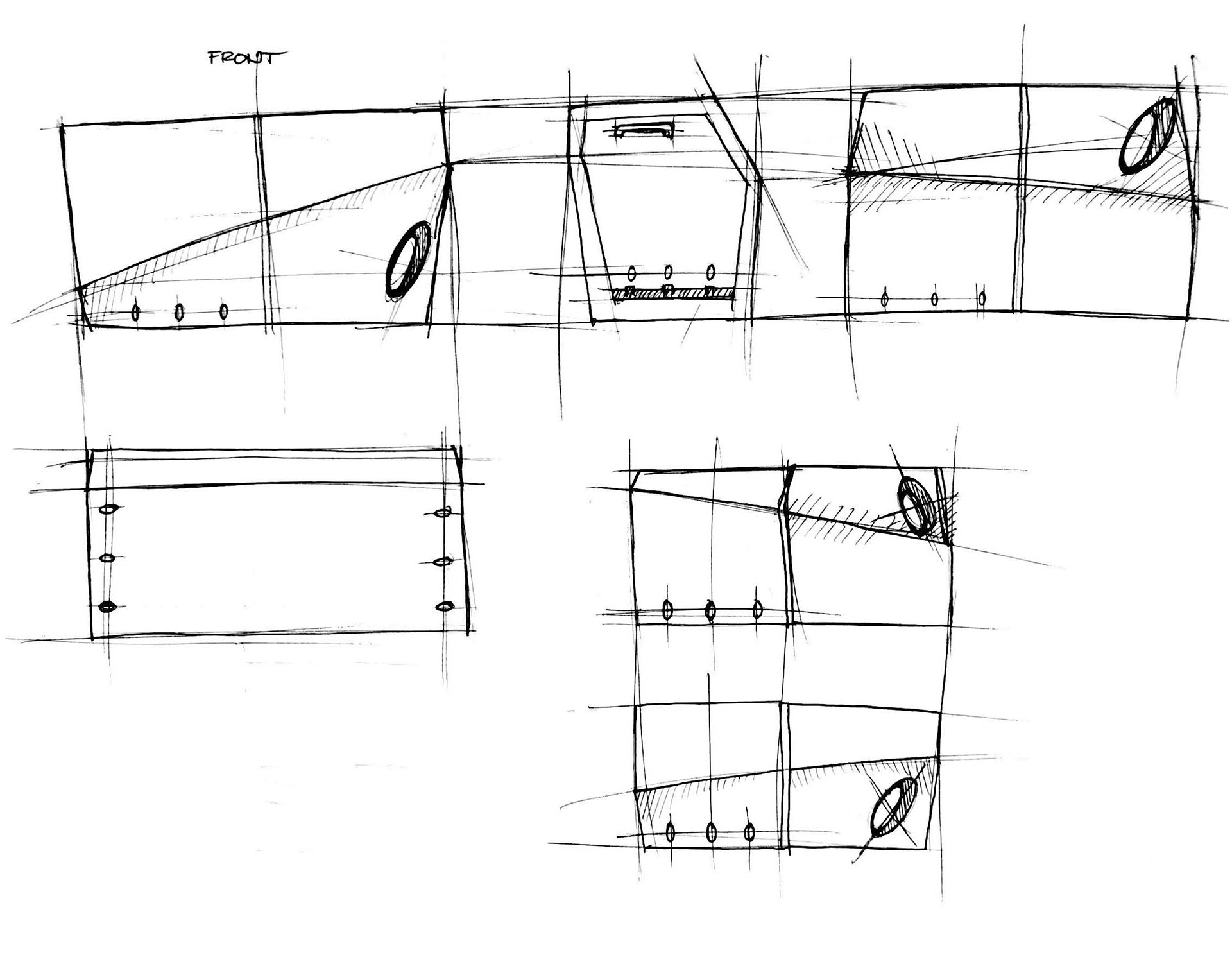

Ideation

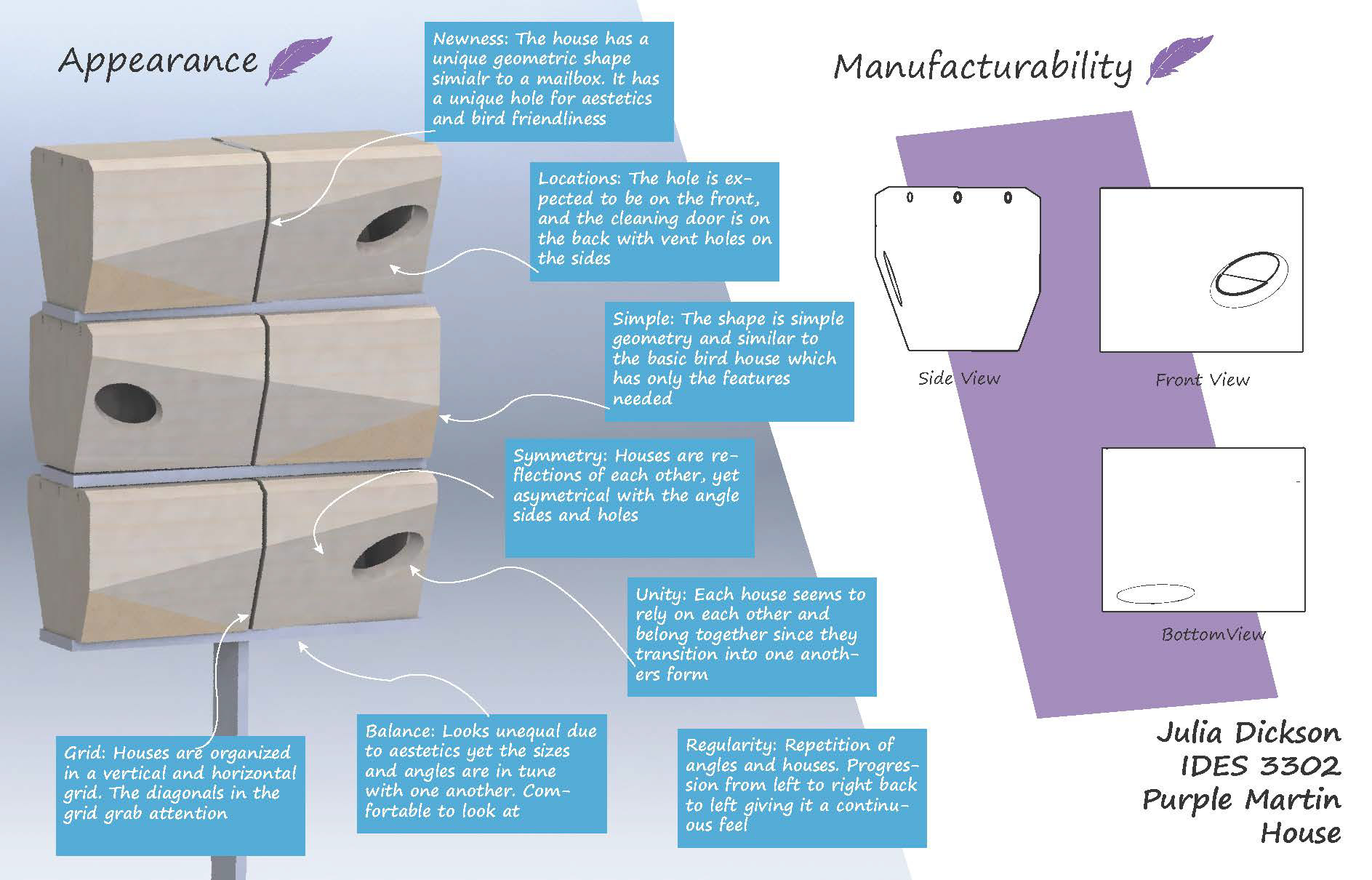

My brainstorming process included getting inspiration from mailboxes, a common product users are familiar with, and with the idea of structure and being connected. I wanted to keep the aesthetics simple for easy manufacturing and easy on the eye.

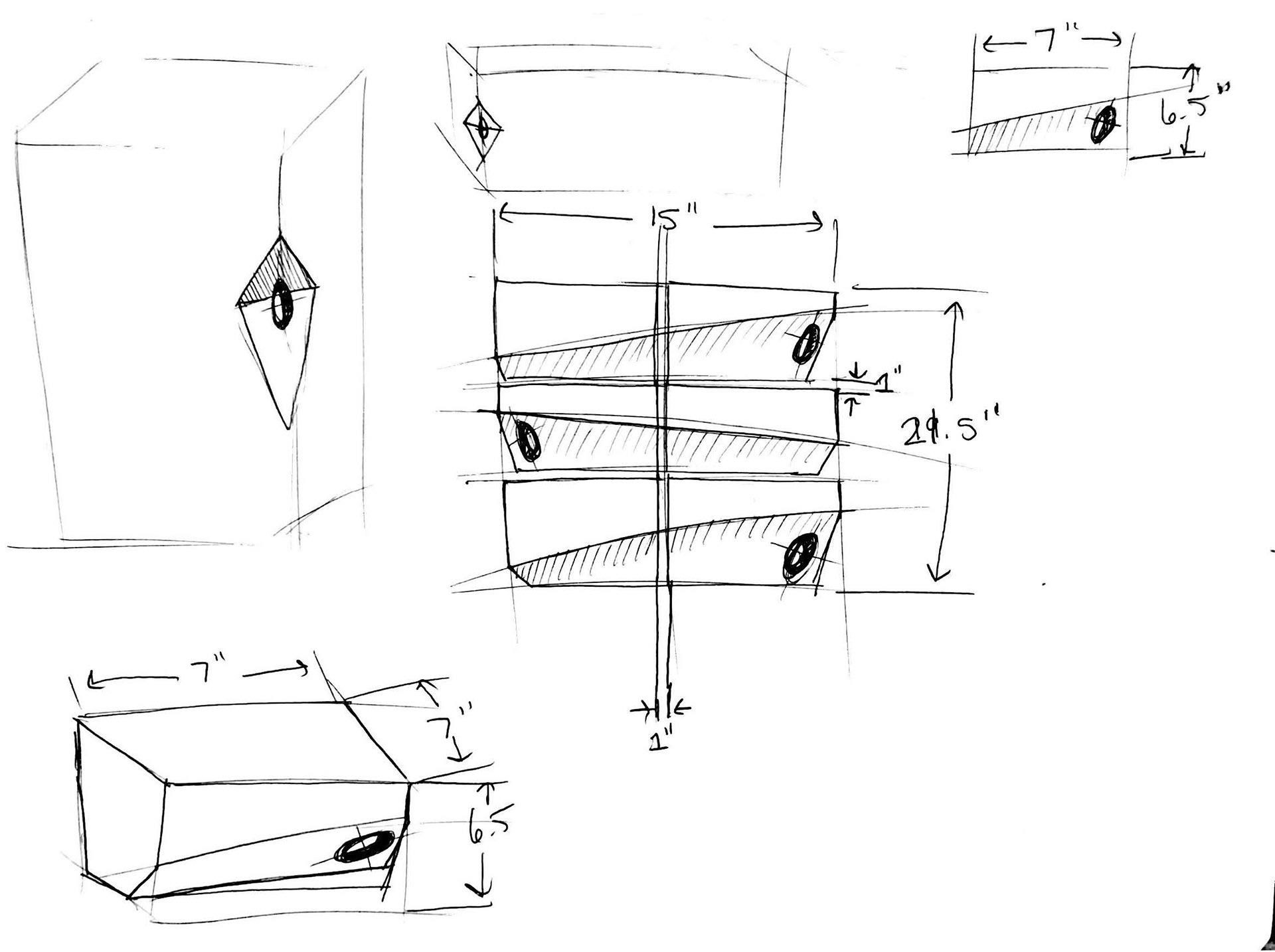

Rough Ideas

Current Bird Houses

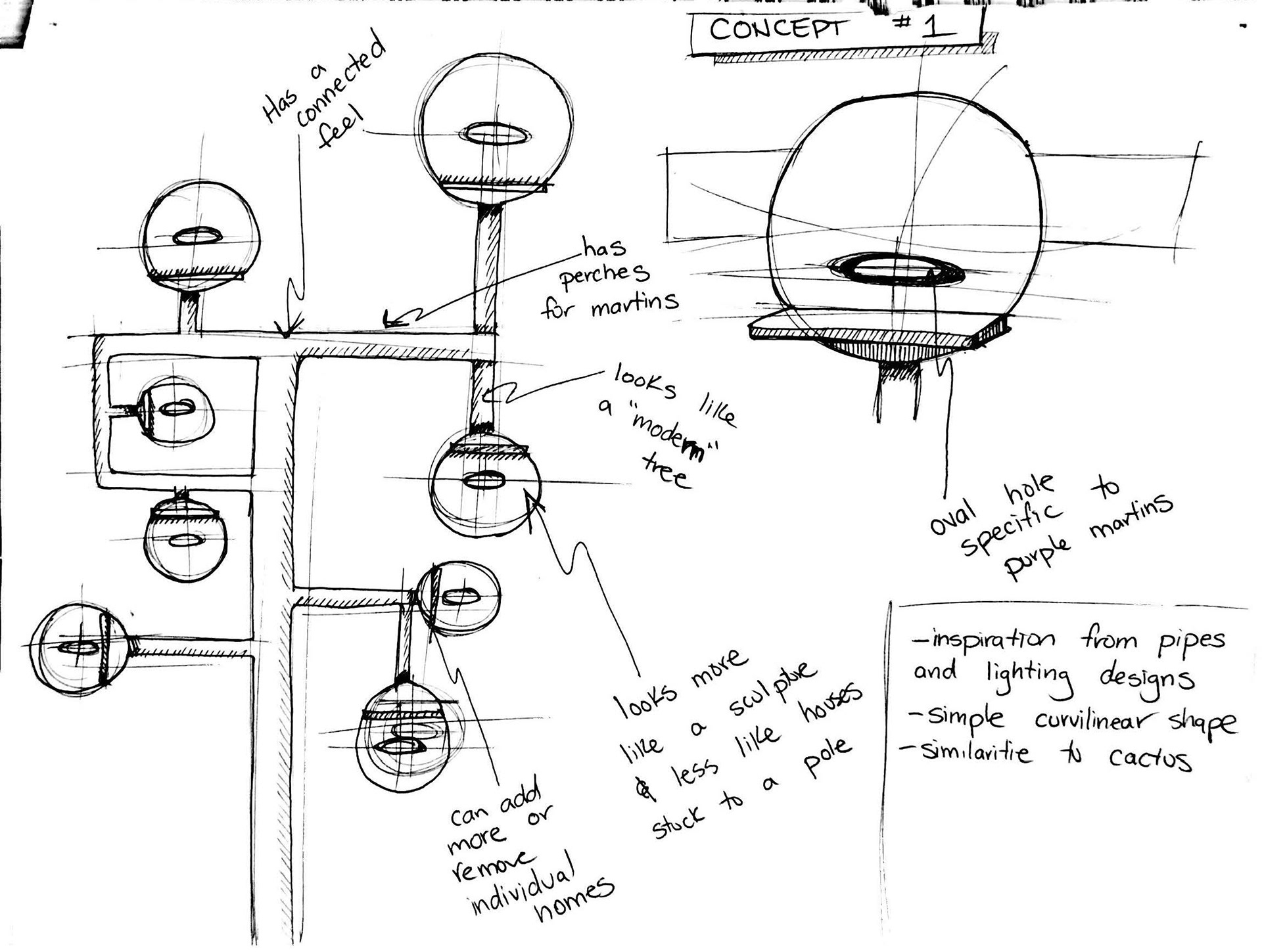

Concept 1

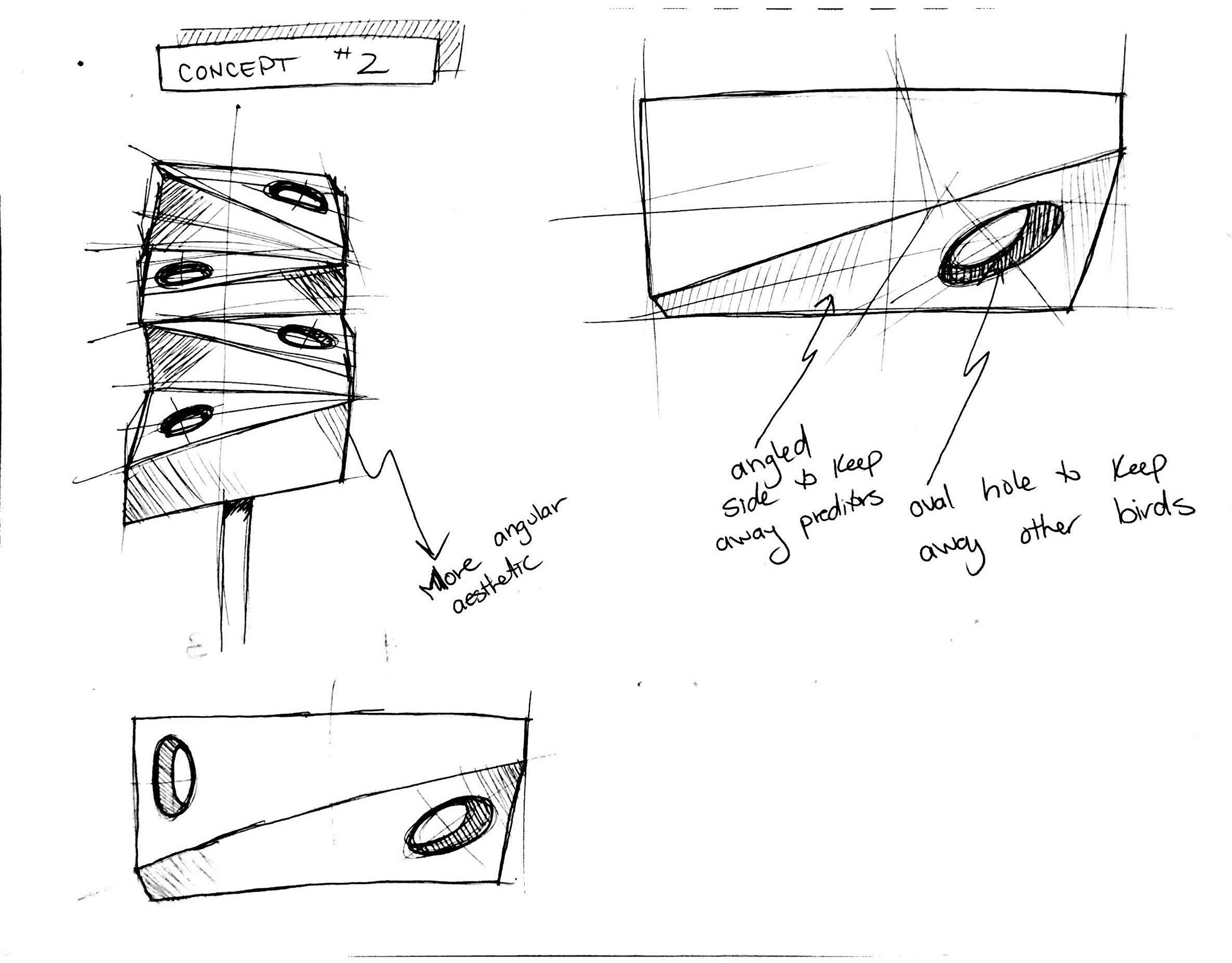

Concept 2

Further Development

Final Concept

Cleaning Feature and Dimensions

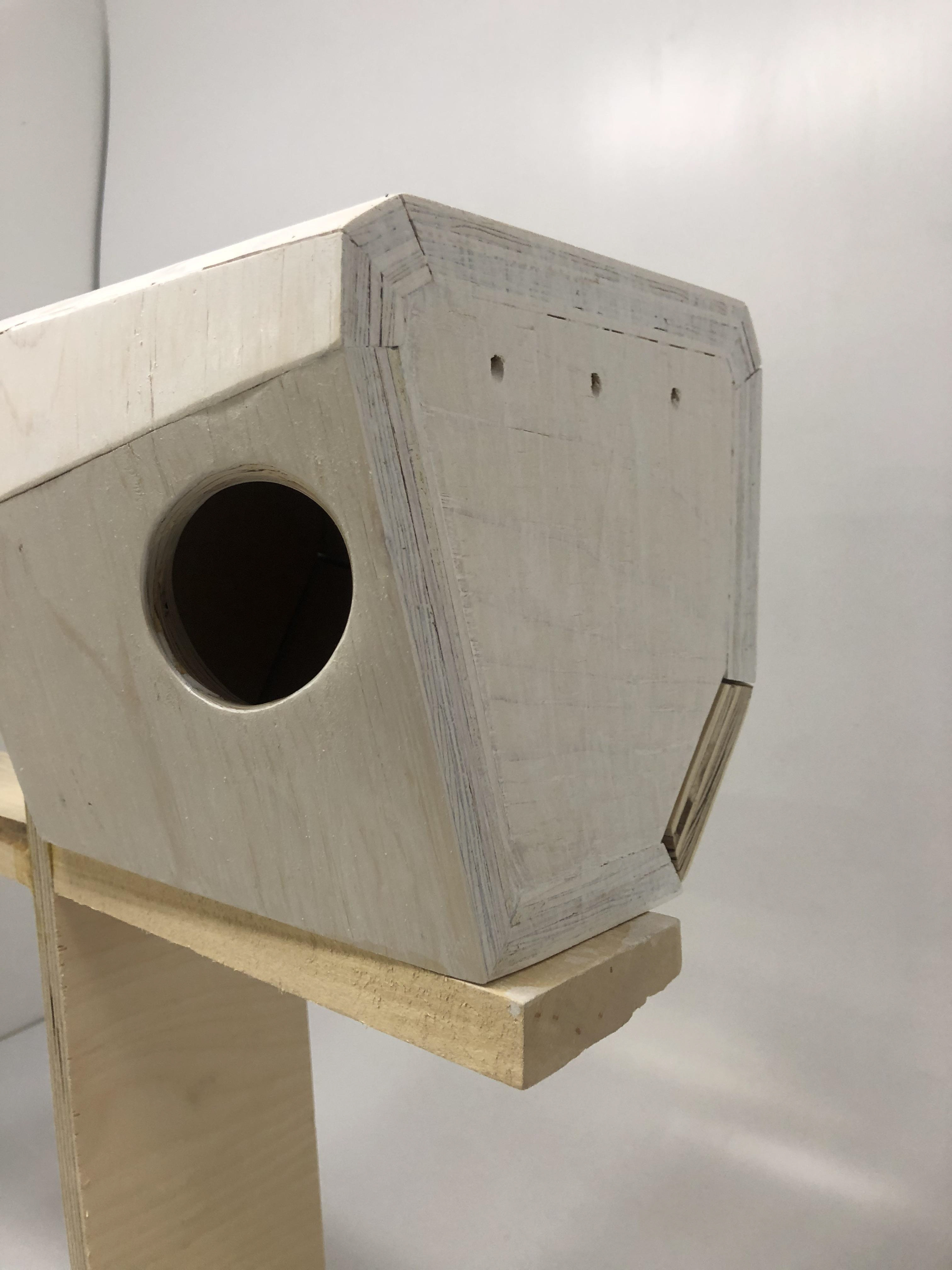

Process

Drilling Hole

Drill Press

Temporary "Glue"

Lining up Pieces

Drying Glue

Testing Hinge

Learning Opportunity

Drilling Vents

Adjusted Design

Painting

Presentation Stand

Magnets

Sanding Angles

Applying Hinge

Hand Sanding

Creating Magnet Holes

Hand Painting

Final Model

Stand

Vent Holes

Back View

Cleaning Feature

Detailing

Final Presentation

My final design was a simple, geometric house that followed all the purple martin requirements. The aesthetics make it an intriguing art sculpture when the houses are not being used in the winter months, and a functional home when the purple martins are present. There is an wood accent with a logo to display branding. The ventilation holes are angled upwards to promote proper drainage and preventing the rain from coming into the nest. The entrance hole is angled as well as are the walls to prevent predators from easily accessing the interior.

Final Renders

Final Boards

Exploded Assembly View

For manufacturing, the bird house base would be assembled by "rolling" it up and wood gluing the faces, then screwing the piano hinge into place to attach the cleaning door and securing the magnets for proper closure. A simple limited step process.